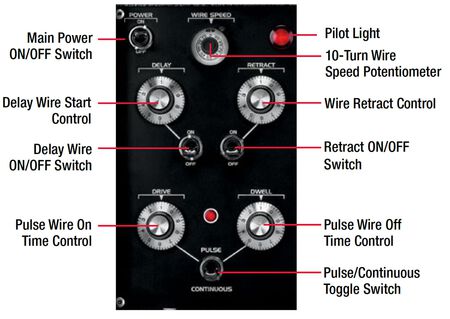

Cold Wire Feed Unit

Automate the addition of filler metal with the touch of a button using the WF-5 Cold Wire Feeder. This machine works independently to provide continuous filler metal for your TIG welding needs.

- Increases productivity

- Automates adding of filler metal

- All parameters can be duplicated for consistency

- Dual groove drive roll accepts multiple wire sizes

- Accepts standard wire spool sizes

- Eliminates filler rod stub loss

- Machine cover keeps filler metal clean and uncontaminated

- Makes fully-automated, or one-handed, TIG welding possible

WF5 Cold Wire Feed Unit

WF5 COLD WIRE FEED UNIT | CK EXCLUSIVE

| Application | Drive Roll | Wire Size | Order # |

| HAND HELD/ MACHINE MOUNTED |

20-35DR | .023" – .035" (.5mm–.9mm) | WF5-030 |

| 30-45DR | .030" – .045" (.8mm–1.1mm | WF5-035 | |

| 30-45DR | .030" – .045" (.8mm–1.1mm) | WF5-045 | |

| 40-35DR | 045" – 1/16" (1.1mm–1.6mm) | WF5-116 |

WF-5 SPECIFICATIONS

Voltage | 115V AC (220V AC 50 hz. —Special Order)

Phase | Single Phase

Frequency | 50/60 Hz.

Height | 15" (38.1cm)

Width | 10" (25.4cm)

Length | 21" (53.3cm)

Weight | 54 lbs. (24.5kg)

Filler Wire Spool Size | 12" (30.5cm)

Filler Wire Sizes | 023" (.5mm), .030" (.8mm), .035" (.9mm), .045" (1.1mm), 1/16" (1.6mm)

Wire Feed Speed Range | 0–700 in/min (0–1,775cm/min)

Feed Time (pulsed mode) | continuously variable

Dwell Time (pulsed mode) | continuously variable

Delay Start Time | continuously variable

Wire Retract Time | continuously variable

Please

Please